Our Sensor System

Are biological imbalances keeping you awake at night?

Wish you had earlier, real-time insight into your wastewater’s metabolic activity so you could adjust operational processes before it’s too late?

Want an inexpensive, no-touch monitoring solution that does all this and saves you money and energy in the process?

Then you’ve come to the right place. Think of our sensor platform as a “heart rate monitor for biology” that uniquely monitors BOD and biomass health in real time providing minute-by-minute snapshots of the treatability of your water or wastewater. Our robust microbial fuel cell-based sensors drop into the most challenging situations and for months without maintenance or cleaning required, highlight microbial activity variations, organic matter degradation, and process upsets which can guide your operational decisions for better treatment outcomes. What’s so unique about our sensors is that the same biofouling that makes other sensors fail in these challenging situations is what makes SENTRY sensors work so well.

Platform Components

Our end-to-end biological activity and water monitoring platform primarily consists of our patented bio-electrode Sensors, our Control Panel, and our supporting web-based management and alerting software.

Bio-electrode Sensors

Our bio-electrode sensors (BES) allow you to reliably measure and monitor the changing BOD or VFA concentrations in wastewater.

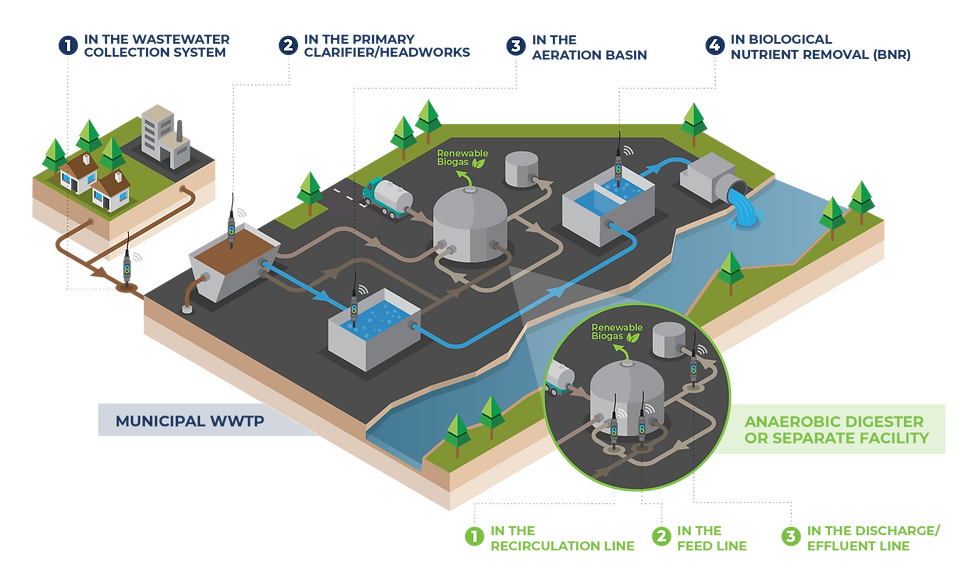

Sensor biofilm is customized to 4 distinct applications, allowing distinct microbial communities to develop that oxidize BOD or VFA in:

(1) wastewater collection networks

(2) influent locations of wastewater treatment facilities

(3) anaerobic selectors for biological nutrient removal

(4) anaerobic digestion environments.

The sensors monitor biological oxidation of organic carbon in wastewater streams by measuring the rate at which in-situ and customized biofilm surfaces consume the available food.

A robust biofilm is established on the sensor after 1-3 days in the wastewater stream. This bio-electric surface then uses the sensor current collector to generate a flow of electrons that is equivalent to the rate of organic carbon oxidation. This flow of electrons is measured and displayed on an online dashboard, and updated every minute. Increasing BOD in wastewater will result in increased metabolic activity and sensor signal, acute chemical toxicity or significant dilution of BOD will result in low alert signals and reduce metabolic activity.

BES-based monitoring like this provides novel, reliable, real-time insight into biological treatment rates and performance. The signals provide a new level of resolution and allow operators to much more closely monitor and detect key triggers of process upset. The bottom line is treatment plants of any sort run on happy, healthy biomass. It’s the key to effective, resilient treatment and processing but traditional monitoring tools are only guessing at how water and wastewater is impacted by biology.

ZERO CALIBRATIONS ZERO MOVING PARTS ZERO ROUTINE MAINTENANCE

Control Panel

This easy-to-install box houses power and communications supporting up to four connected SENTRY bio-electrode sensors.

_edited.jpg)

Custom Web Dashboard

Our supporting online dashboard works across all Internet-connected devices and allows you to easily monitor real-time performance of resident microbiology, receive customized early warning alarms for system imbalances and toxic events, log these events, and share data remotely. Real-time SENTRY data is also sent to on-site SCADA systems.

Installation Options

Our bio-electrode sensor system can be installed and start collecting data in as little as 30 minutes thanks to our plug-and-play approach that plugs into a standard outlet and begins wirelessly transmitting data to our web dashboard. Additionally, the system is equipped with analog, Ethernet, and Wi-Fi connectivity options that ensure data access regardless of the installation location.

The sensors themselves can be installed in both drop-in and in-line locations and can withstand the most challenging environments since the same biofouling that makes other sensors fail is what makes SENTRY sensors work so well.

Drop-in Installation

SENTRY™ can be added to existing tanks and systems. Custom mounting solutions can be provided for each install location and environment if required.

In-line Installation

The in-line sensors are installed and connected through a 1.5” NPT fitting into a pipe with at least 3” diameter. Typical installation for a single sensor is in the recirculation line of the anaerobic tank, but if sequential tanks are present - for hydrolysis, acidogenesis etc. – a probe installation in each tank is recommended.

System Maintenance

Entirely powered by the biomass representative of your system, our systems have no moving parts, membranes, or consumables and are virtually maintenance-free. Our sensors perform best in conditions that foul other sensors, which must be regularly inspected, cleaned, and calibrated.

When we say

low maintenance,

we mean

low maintenance.

Installed 18 months apart;

no touch, no clean, no drift

6 months later.

SENTRY in the Wastewater System

The robust nature of our sensors provides more installation options throughout a typical wastewater system.